Work Order and Job Card Booking in ERP

Work Order and Job Card Booking in ERP

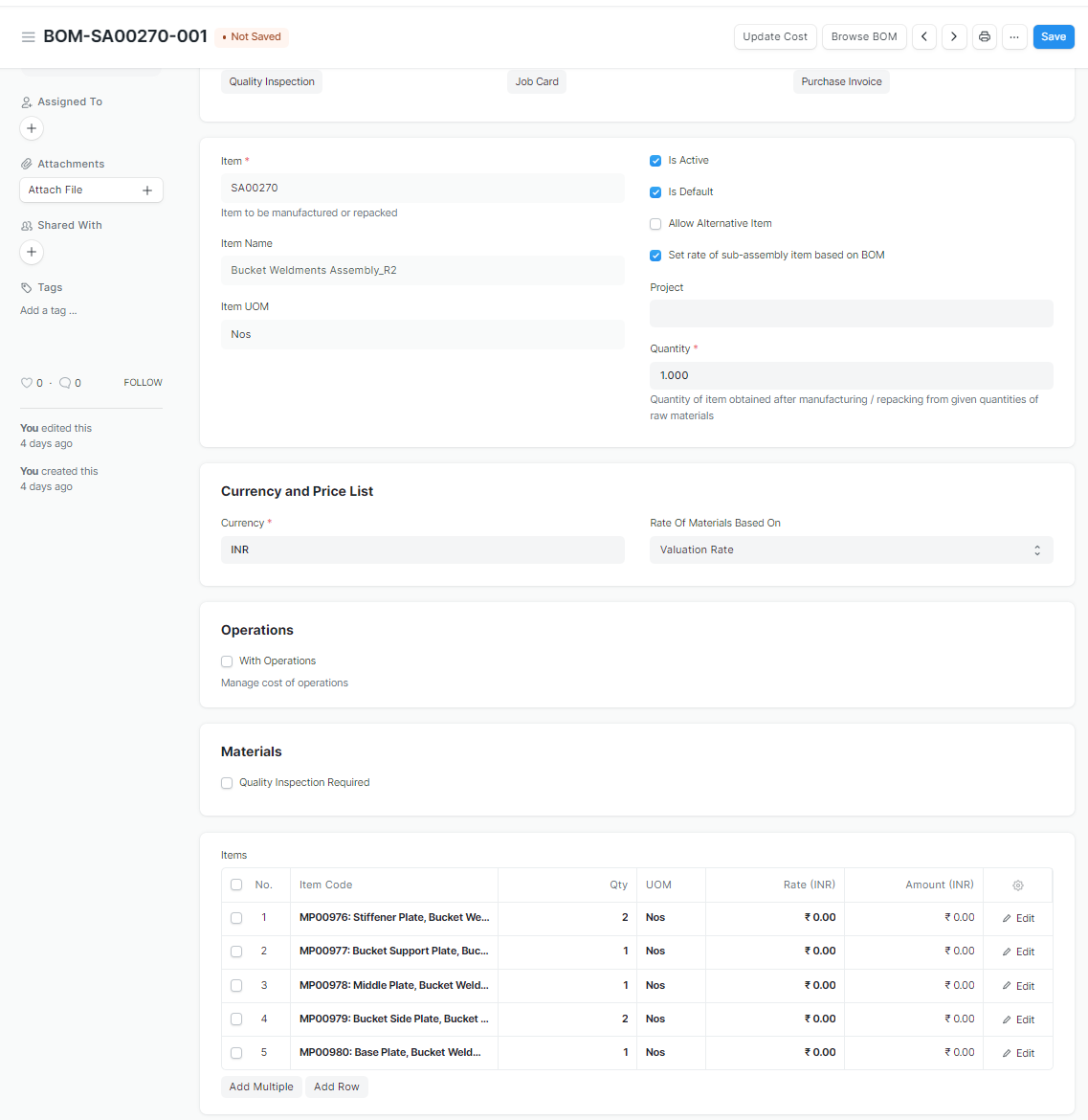

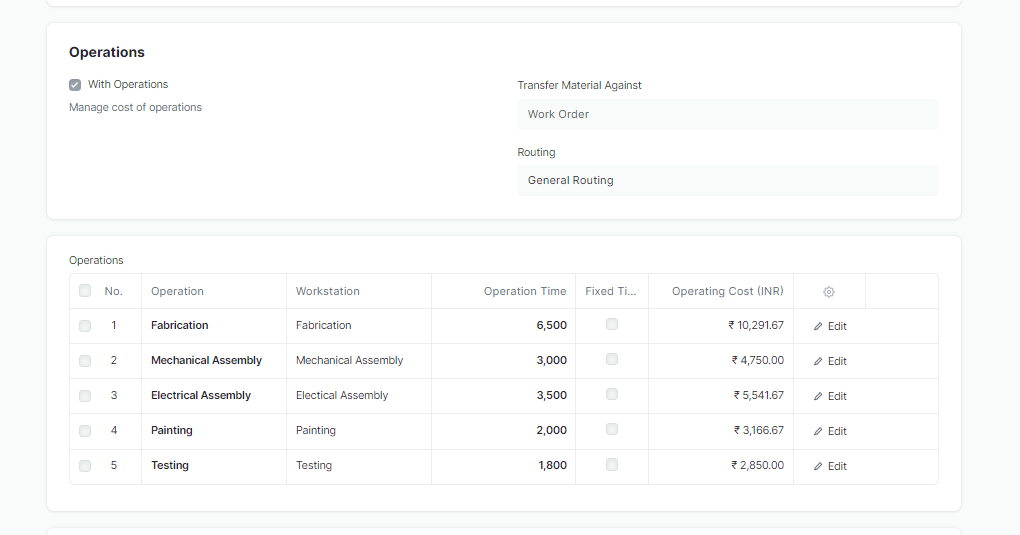

All items being manufactured in-house are covered under the item groups 'MP: Manufactured Part', 'SA: Sub-Assembly'. These items will be invariably having Bill of Materials (BOM) consisting of Raw material for Manufactured parts and one are more items (SP, BP, SA, MP) for Sub-Assembly items along with quantity required to manufacture one number of the higher level item. These items will also have operations defined in BOM. The operations can be created individually along with workstation and planned timings maintained or copied from a template. A common template consisting of Fabrication, Assembly, Electrical Assembly, Painting and Testing is available to be used for BOM.

Production planning / methods person has to maintain these operations and timings after the design has finalized the BOM template and created BOM through CAD Interface module (Details of this module is available in earlier blog https://bullwork.frappe.cloud/blog/erp-process/cad-interface-module). BOM has to be approved before using this item in higher level BOM.

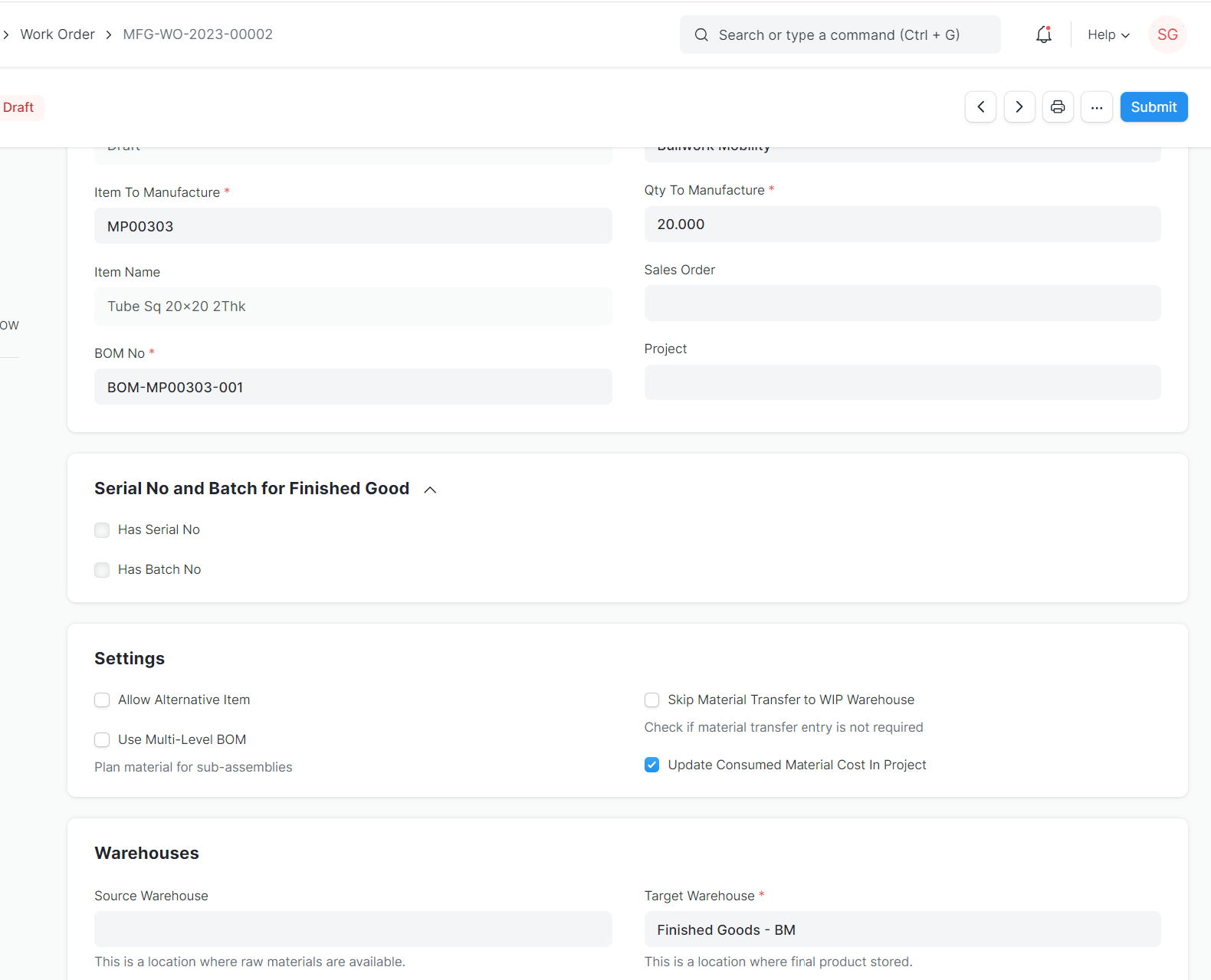

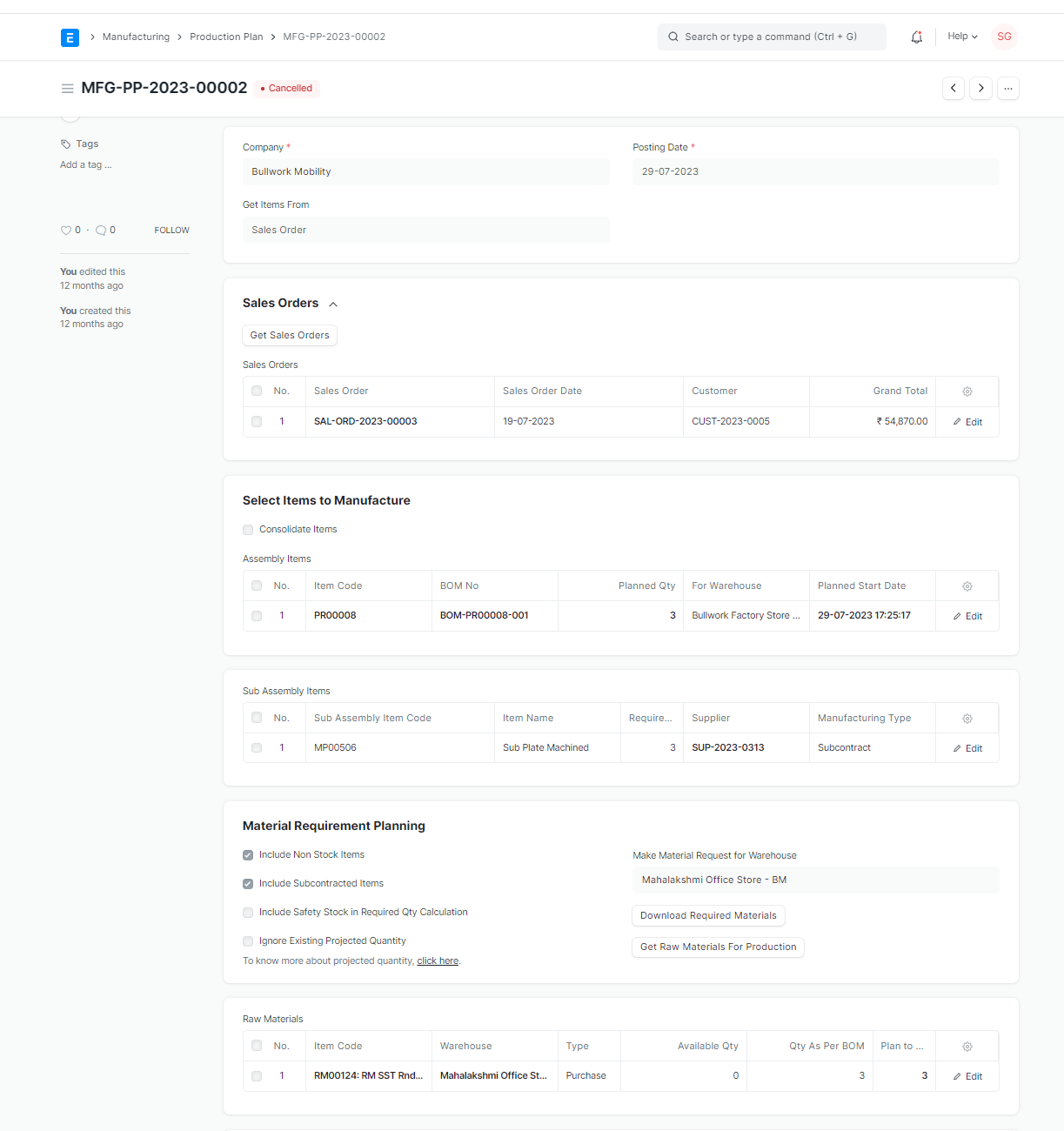

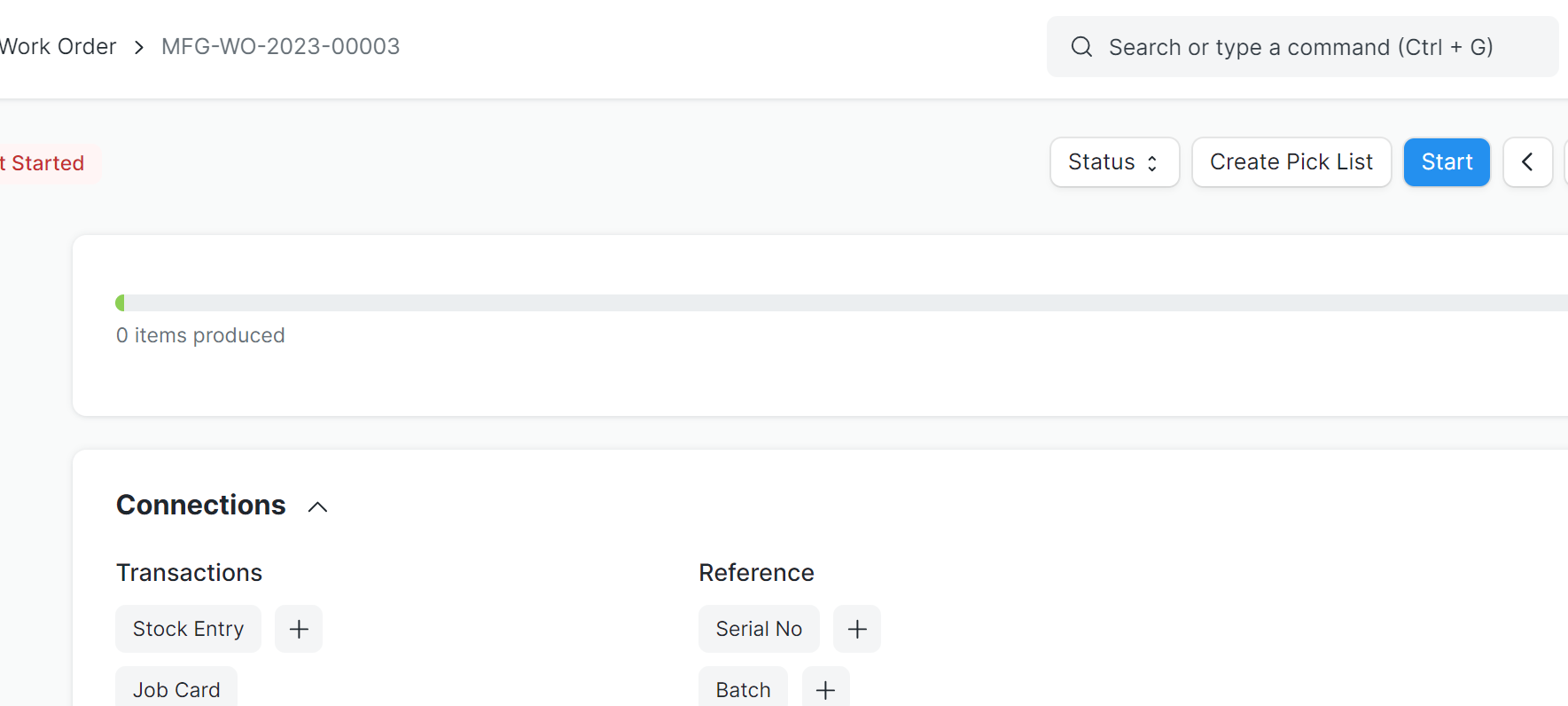

Work orders for the planned items can be created individually based on Material Request for manufacture of an individual item or through Production planning tool for a given assembly from a approved BOM. When these work orders are submitted, Job cards for the corresponding operations are created.

The items required for the Work order can be generated through pick list and sent to stores for issue.

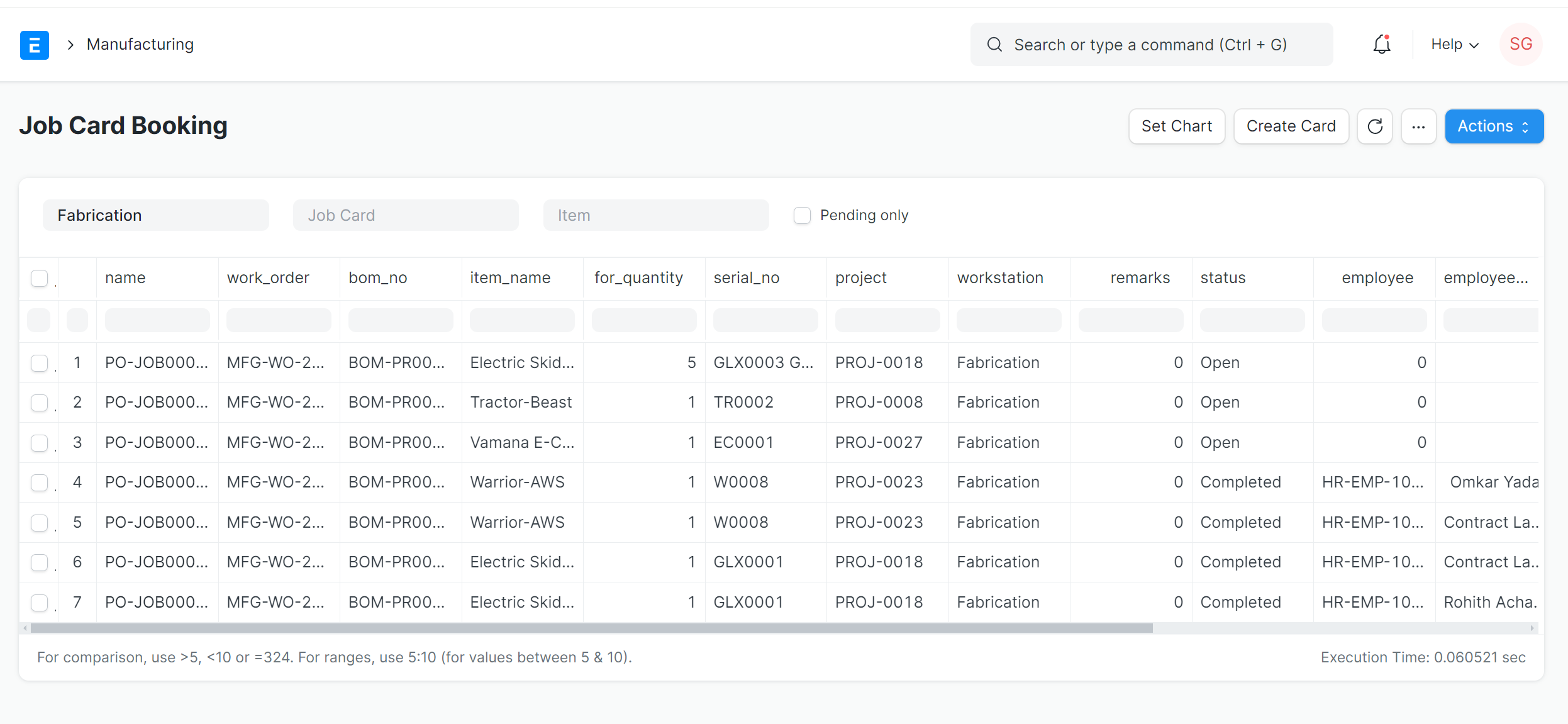

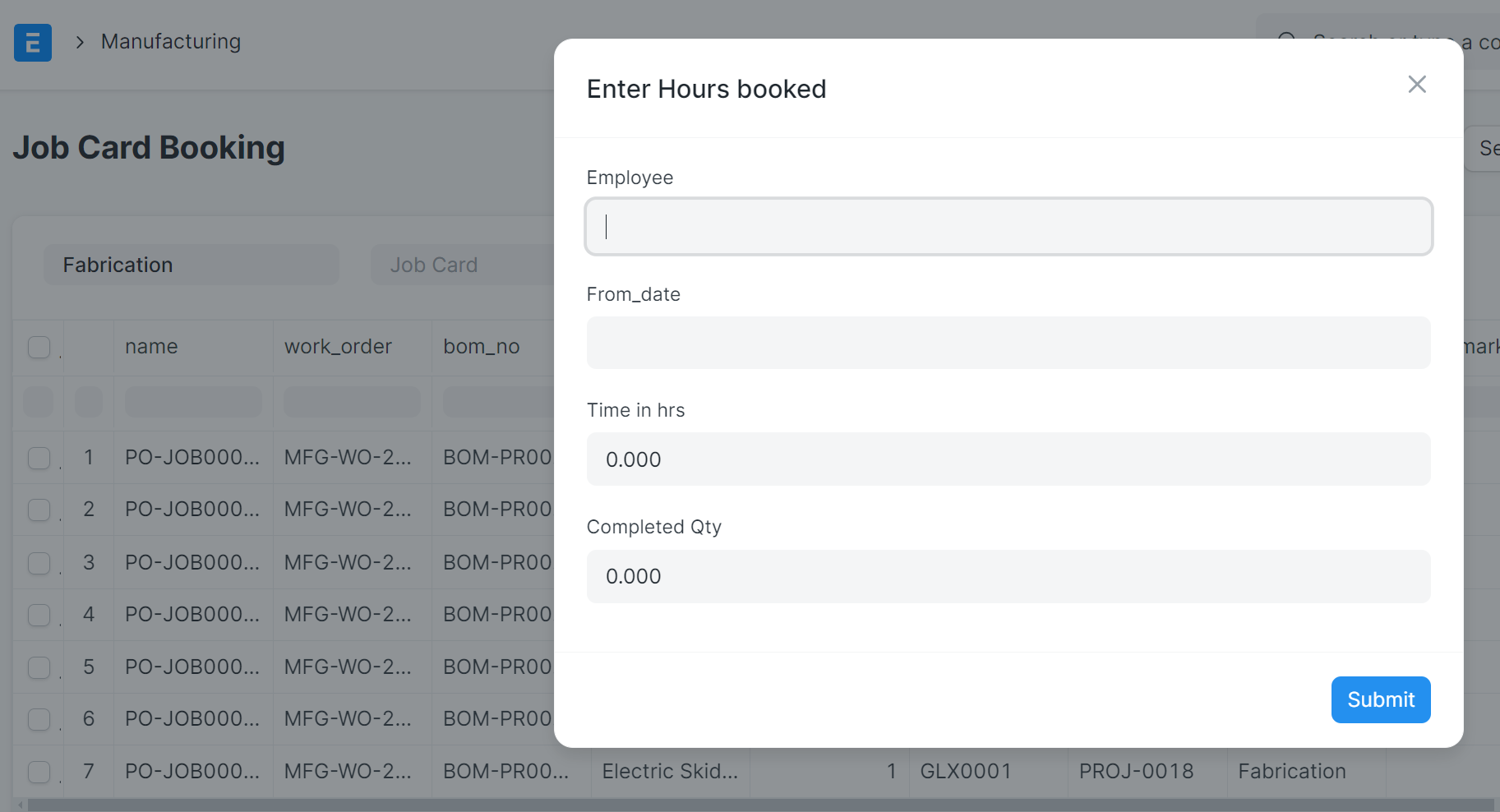

After completion of each operation the timings in hours have to be booked and closed. In order to facilitate this process a custom report is introduced through which list of jobs for a workstation can be viewed and job card booking can be done as shown. PDF print for a workstation on a given date can be displayed near the workstation for information.

On closing the work order, the higher level item will be the output with the value of item being sum of cost of all materials consumed as per BOM and operations cost as per booked hours.

For the items which are currently running in the Production, workorders and job cards at highest level has been created and these job cards are being closed with hours and cost booked in respective Project is being transferred at the time of closing the work order so that the output material will be valuated at that rate.

Further when product BOM is firmed up in the ERP, the manufacturing process in-house will be through production planning tool where workorders get created for each item.

For further readings please visit https://docs.erpnext.com/docs/user/manual/en/manufacturing

No comments yet. Login to start a new discussion Start a new discussion